CCA Conductors Instead of Aluminium or Copper?

October 6, 2023

Cables labelled as CCA are offered by numerous retailers and online cable and wire providers. HELUKABEL provides an explanation of this terminology.

Copper conductors are typically preferred for most cables and wires due to their high conductivity, flexibility, tensile strength, and cost-effectiveness. These qualities make copper the ideal choice for a variety of applications. In some cases, conductors made of aluminum are used, particularly in energy transmission.

However, aluminum has a conductivity of only about 63 percent when compared to copper. This results in a higher voltage drop and reduced current-carrying capacity for the same cross section. To attain equal voltage drop and current capacity as copper cables, larger cross sections are required for aluminum cables. Furthermore, aluminum is more prone to breaking than copper when subjected to multiple bends, resulting in weaker bending resistance. Therefore, aluminum cables are primarily used for fixed installations or low mechanical stress.

When aluminum comes into contact with bare copper, an element formation occurs, leading to corrosion. Therefore, aluminum cables require a separate connection technology that must not use cable lugs intended for copper cables. Instead, only specially approved connection products should be used. Handling, tools, and specialist knowledge required are also unique.

The benefits of aluminum as a conductor material are due to the lighter weight of the cables. As a result, aluminum cables are utilized in all building constructions where overall weight is an important factor, such as in power lines. Another advantage is that aluminum cables are less expensive than copper cables, despite their larger cross sections, as the raw material cost for aluminum is lower than that of copper.

The comparison of two conductor cross sections based on IEC 60228 Class 2 having similar conductance is as follows:

- A 240 mm² (500 kcmil) aluminum conductor weighs approximately 723 kg/km.

- For a 150 mm² copper conductor, the weight is around 1341 kg/km.

- Despite the increase in cable thickness, the weight reduction achieved through the use of aluminum can reach up to 30-40 percent, depending on the specific design.

What does CCA mean?

CCA stands for “Copper Clad Aluminium”. The cables consist of an aluminum conductor with a thin surface layer of copper, typically comprising around 10 percent copper and 90 percent aluminum. These conductors were developed as an economical alternative to high-frequency cables for fixed installations, such as antenna technology. It’s important to note that sound signals are not transmitted over the cross section, as with electricity, but rather over the surface of the conductor. This phenomenon is known as the skin effect: at higher transmission frequencies, the conductor surface is primarily utilized for transmission while the cross section plays a secondary role.

For several years, there has been a proliferation of products labeled CCA among European retailers and online vendors. Most of these items originate from Asia and are found in the affordable price range.

- Speaker

- Power cable for car Hi-Fi (to power the amplifier)

- Network cable (patch cord with plug)

In theory, CCA cables could serve as loudspeaker wires, though caution is advised. Hi-Fi enthusiasts specifically seek out wire with a larger cross section, aiming for the lowest possible resistance and loss-free transmission. However, using a CCA cable with a AWG14 (2.5 mm²) cross section equates to a copper cable with only around AWG16 (1.5 mm²) conductivity, resulting in poorer transmission quality. However, many sellers and shops fail to highlight this distinction.

Power cables used to supply amplifiers in car hi-fi systems carry substantial current. As a result, the user must properly secure this and any subsequent installation, or risk voiding the vehicle’s comprehensive insurance in the event of a fire. Nevertheless, private users may often lack the requisite technical expertise. He is unaware that the purchased CCA power cable has poorer conductivity. A cross section of AWG4 (25 mm²) CCA corresponds to approximately AWG6 (16 mm²) of copper cable, increasing the risk of fire since the fuse is not selected appropriately.

From a technical standpoint, CCA cables have limited use as network cables. Nevertheless, due to the widespread use of “Power over Ethernet” technology, these cables are frequently used for power supply. This results in the same problem encountered with connection cables in the hi-fi sector, which is the occurrence of a higher voltage drop as a result of CCA’s greater resistance. The outcome is a decrease in the cable’s operating length and an increase in heat generation, both of which elevate the risk of damage. The TIA standard in Britain similarly forbids the use of network cables with CCA conductors for Cat 5e, 6, 6A, 7 and 8. Copper-coated aluminum cables are also not allowed, according to the IEC 61156. Although suitable for short distances in a home office environment, these cables should be avoided in a professional company network, which must operate smoothly and trouble-free for many years.

What else is there to know about CCA?

- Lower tensile strength than copper conductors

- Lower corrosion resistance (aging)

- Lower melting point

- Due to lower conductivity, the cables heat up more when using “Power over Ethernet” and the voltage loss is higher

- Recycling is considerably more complex

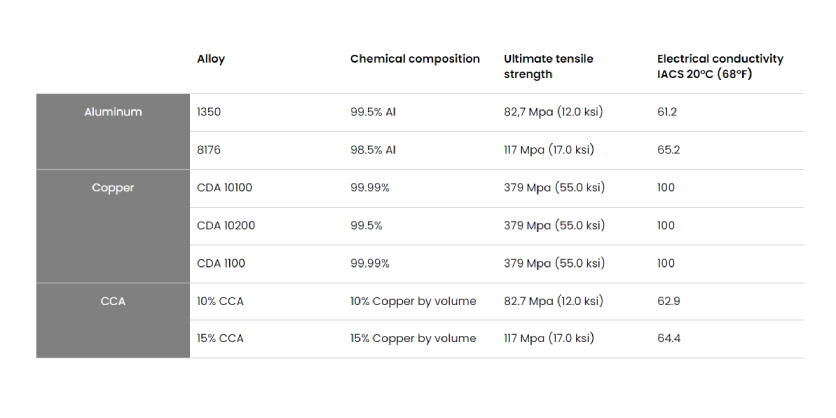

Comparison of electrical and mechanical values of the various conductor materials

Summary

CCA cables must be handled with caution due to the insufficient education provided to dealers about this material.

The use of aluminum cables has significant weight advantages, and they should only be installed and planned by experts due to the material’s unique characteristics if improperly handled. Aluminum cables are recommended for situations where space is not a central concern – such as wind turbines or battery cables in vehicles. It is critical to use the appropriate connection technology with aluminum cables. Energy suppliers now exclusively use aluminum conductors for medium-voltage infrastructure cabling. The standardized underground cable NAYY, conforming to DIN VDE 0276-603, is a widely known example of an aluminum cable.

Copper cables, which are also commonly used, can be implemented by private individuals with appropriate knowledge and manual skills.

About the author:

Horst Messerer is Product & Sales Manager Data, Network and Bus Technology at HELUKABEL.

Related Story

Why Use VFD Cables? HELUKABEL Answers

Why Use VFD Cables? VFD cables are a critical component to extend a motor’s life cycle within a VFD system. Three areas where VFD cables set themselves apart from traditional tray-rated power cables are: 1. Address high and low frequency noise issues with proper shielding, 2. Ability to withstand voltage spikes/reflected wave voltage, and 3. High temperature resistance