is special.

Drying after

Surface finishing, Painting and Cleaning

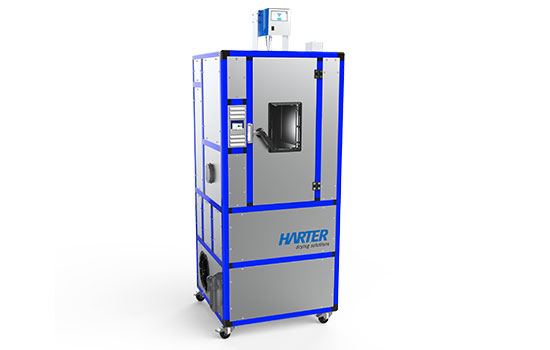

The HARTER purpose devised Airgenex® drying technology is capable of drying surfaces and solid matter of all kind in a gentle and energy saving way, plus reliably and fast. This so-called heat pump based condensation drying resolves drying problems and optimizes manufacturing processes.

On the following pages, you – no matter if you are a plant operator, construction company or planning office – may find advantages of our drying technology, how it works and where it is applied.

Your Benefits

Very fast

Airgenex® condensation drying saves you 50% of time required by conventional drying methods, such as hot air drying or simple fan-based systems. You will be surprised how much we can reduce your drying time!

Very reliable

The dehumidification process takes place in a system which is closed in terms of thermal energy. Our drying systems are thus completely independent of effects of the climate and the weather. This ensures highest process reliability for you. Plus you are on the safe side if production quantities need to be raised.

Very efficient

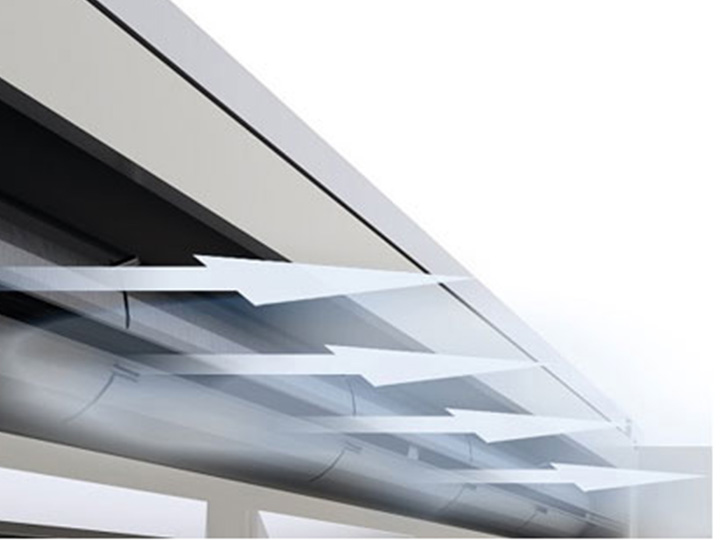

The heart of the Airgenex® dryer is a highly efficient heat pump based dehumidification module. Components installed are the best available, some of them purpose built for us, and are made from high grade materials. We combine air dehumidification with sophisticated air routeing such that the dry process air is directed only to where it is supposed to absorb humidity. Also, drying is effected in a closed system with heat recuperation. This makes drying take full effect while being extremely cost effective.

Very gentle

Airgenex® dries products or materials at low temperatures between 20°C and 90°C as required for the specific application. This low temperature drying prevents undesired heating of the materials and products. Stain-free parts and reduced reject quantity means higher productivity for you.

Applications

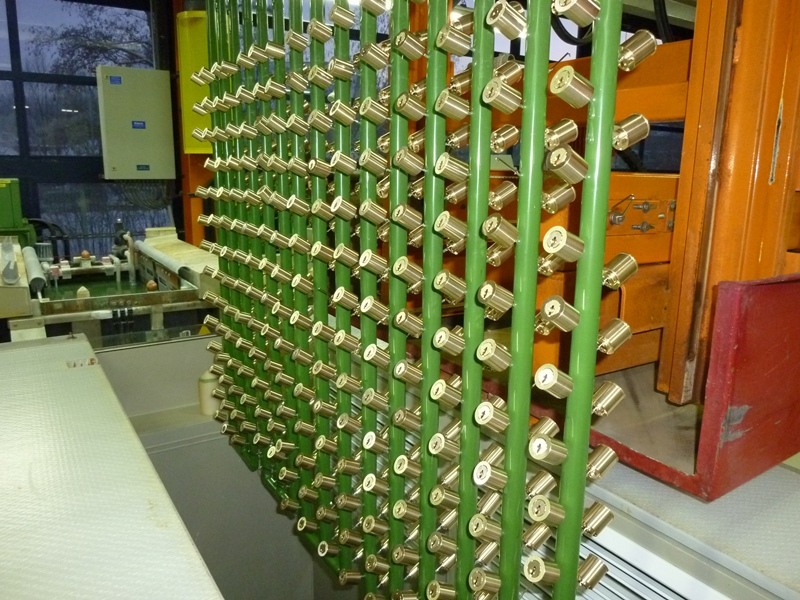

Factors which will optimise the efficiency of the drying process vary for each application. In-barrel drying of bulk material poses challenges much different from those of drying racked products with complex geometries or painted surface.

The most common applications are shown below.

Your application is different?

You will surely understand that, with more than thousand drying systems installed, we cannot possibly list all our potential applications. If your application is not listed above, please do not hesitate to contact us. We will be glad to give you advice without engagement on your part!

The Process

We dry using dry air directed to the right places: A perfect interaction of air conditioning and air routeing provides the best drying result possible.

Click at the numbers inside the graphic to get further information.

Our test center is unique.

A room full of technical equipment and opportunities.

A place full of creativity and innovation.

Tinkers with experience and inventive spirit.

Clients with faces in wonder.

Please, come in!

Tests provide valuable Information and Confidence

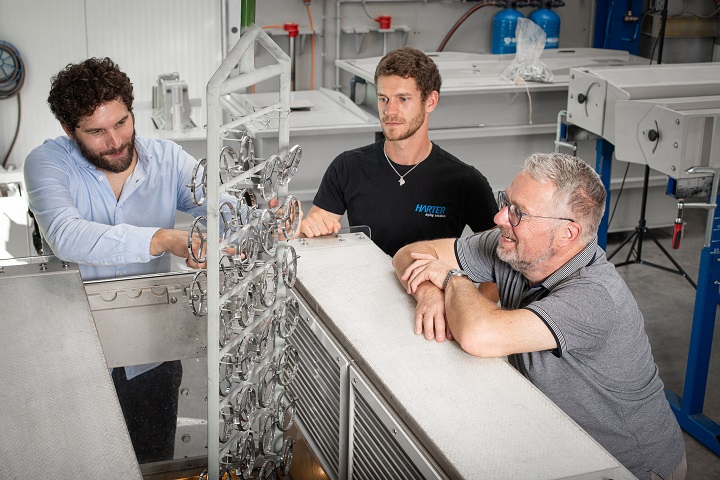

Series of tests run in our test center provide valuable information and confidence. We test your product for response to temperature, time, humidity, air speed and airflow rate. We also look at the routeing of the air inside the dryer because this is a critical factor on the way to success. To do all this, we have several multifunctional dryers which our engineers adapt to the specific application. Our service to you includes, of course, an evaluation and interpretation of, and a comprehensive report on the results of these tests.

Sometimes, the solution is clear at hand after just one series of tests. Every now and then, numerous series with varying parameters are required. This is the moment when it takes our resourceful engineers with all their creativity to find a good solution. And they always find one.

We have run thousands of drying tests in our test center in more than 30 years. The experience gathered and the know-how obtained therefrom may not be valued high enough. And it is for your benefit.

A Day filled with more than just Engineering Matters

You are welcome to witness our tests. See with your very eyes how powerful our condensation drying is and how we create viable solutions. We will give you an insight into drying issues relating to your product. We also cultivate hospitality and good company. So, your stay will be both pleasant and informative.

Our Special Service

It may appear reasonable to run drying tests at your premises using a system provided on loan. In such case, one of our qualified engineers will instruct you on how to run your own tests. We also build larger scale test set-ups as agreed.

You are a Manufacturer and want a better Dryer?

You already have a product and a process but are less than satisfied with your existing drying system? Or the high energy consumption is no longer acceptable? You want to change something? Maybe you are unsure if our technology keeps what is promises?

Our test center will provide answers to your questions. You tell us the ideal conditions under which your product should get dry. As an outcome of our tests, we will furnish a solution. The results are very often much better than expected by our customers. Our process, for example, will often be short of the specified cycle time. When it comes to drying bulk material, we can routinely stun our customers.

You are Planning Something New and are Uncertain as to Exactly how?

Do you intend to change from alcoholic to aqueous cleaning? Or you intend to use water-soluble paint only? Perhaps you stop using solvent-based adhesive? Or you are planning to introduce an entirely new product?

Whatever the challenge to be met we will be glad to deal with it. It is our passion to find the best drying solutions. When running tests, our engineers quickly see which process is best suited to ensure successful drying. If products are particularly demanding there is always an engineering trick to help us arrive at a solution.

You are a Subcontract Processor of a Wide Range of Products?

Let us suppose you are a subcontract electroplating company processing a wide range of products. You might not know yet which products you will process in the future. In such situations, our tests will reflect the most complex items to be dried. We will allow for some extra margin to give you maximum assurance. This way we can ultimately ensure that our system will be capable of covering your whole range of products today and later.

Our pilot plant station is a place where ideas are forged. People who can think creatively and alternatively work and tinker here. It is a place where challenging tasks turn into reliable solutions.

Reinhold Specht

What can we do for you?

SALES

You are welcome to contact us without obligation.

+49 (0) 83 83 / 92 23 11 | info@harter-gmbh.de

AFTER SALES SERVICE

Our friendly staff will be happy to assist you.

Monday to Thursday from 8 a.m. to 12 p.m. and 1 p.m. to 4.30 p.m.

Friday from 8 a.m. to 2 p.m.

+49 (0) 83 83 / 92 23 20 | ass@harter-gmbh.de

BROCHURES & PRESS

- Harter 2023 Scania paint drying

- Harter 2023 Paint Drying the Energy Efficient Way

- Harter 2023 Watches Dries in Continuous Operation

- Harter 2023 The Art of Drying

- Harter 2023 Drying Electronics Feszo Hungary

- Harter 2023 With Government Support to the latest Drying Technology

- Harter 2023 Static Drying of Bulk Material

- Harter 2023 Saving Energy and Cycle Time with Novel Drying

- Harter 2022 Selective Stain-free Drying

- Harter 2022 Drying be the tousands

- Harter 2021 A Drying System Needs to be Carefully Wrought

- Harter 2021 Reliable Large Volume Drying FYSAM

- Harter 2021 Drying-Brought into Line Phoenix

- Harter 2021 Drying in a Cleanroom Gewiss

- Harter 2021 Drying Insulating Panels

- Harter 2021 With Government Support to the Latest Drying Technology

- Harter 2020 Large Capacity Dryer for Higher Throughput VDL

- Harter 2020 Gentle Drying of Carbide Inserts Tigra

- Harter 2020 Reliable and Stain-free Drying STS

- Harter 2019 Alanod Belt Drying

- Harter 2019 ZF drying helicopter gearboxes

- Harter 2019 Hansa stain-free drying of fittings

- Harter 2019 Stiwa drying after vibratory finishing

- Harter 2019 Uniform Drying of Bulk Material from Manufacturing Processes

- Harter 2019 KKS cleaning drying watches

- Harter 2018 Drying Projects Switzerland

- Harter 2018 Ceratizit Drying Metal Rods after Cleaning

- Harter 2018 Zinc Coating Shop Kriessern Sludge Drying Barrel Drying

- Harter 2017 Drying Bulk Material after Cleaning

- Harter 2017 Claudius Peters Aircraft Drying

- Harter 2017 Paint Drying Scania

- Harter 2016 Drying Coatings Tyrolia

- Harter 2016 Efficient Drying SMK

- Harter 2015 Paint Coated Sensor Houses Sick

- Harter 2015 Dryer Pickling Line Audi

- Harter 2015 Drying Plastics Fischer

- Harter 2015 Ceratizit

- Harter 2011 CeramTec

- Harter 2010 Paint Drying Hertfelder

- Harter 2010 Drum Drying Ruag

- Harter 2009 Rack Drying Comte

- Alternative Drying Technology Qualifies for Government Subsidy

(published in in Werkstoffe in der Fertigung 1/2021) - Aviation – Drying a Safety Factor

(published in in JOT – 61 (2021) Special Edition 3) - With Government Support to the Latest Drying Technology

(published in in mo – Magazin für Oberflächentechnik 1-2 2021) - Gentle Drying of Carbide Inserts

(published in in mo – Magazin für Oberflächentechnik 8-9 2020) - Large Capacity Dryer for Higher Throughput

(published in in JOT Industrielle Teilereinigung 2020)

Unser Technikum ist eine Ideenschmiede. Hier arbeiten und tüfteln Menschen, die kreativ und alternativ denken können. Es ist der Ort, an dem wir schwierige Aufgaben in sichere Lösungen verwandeln.